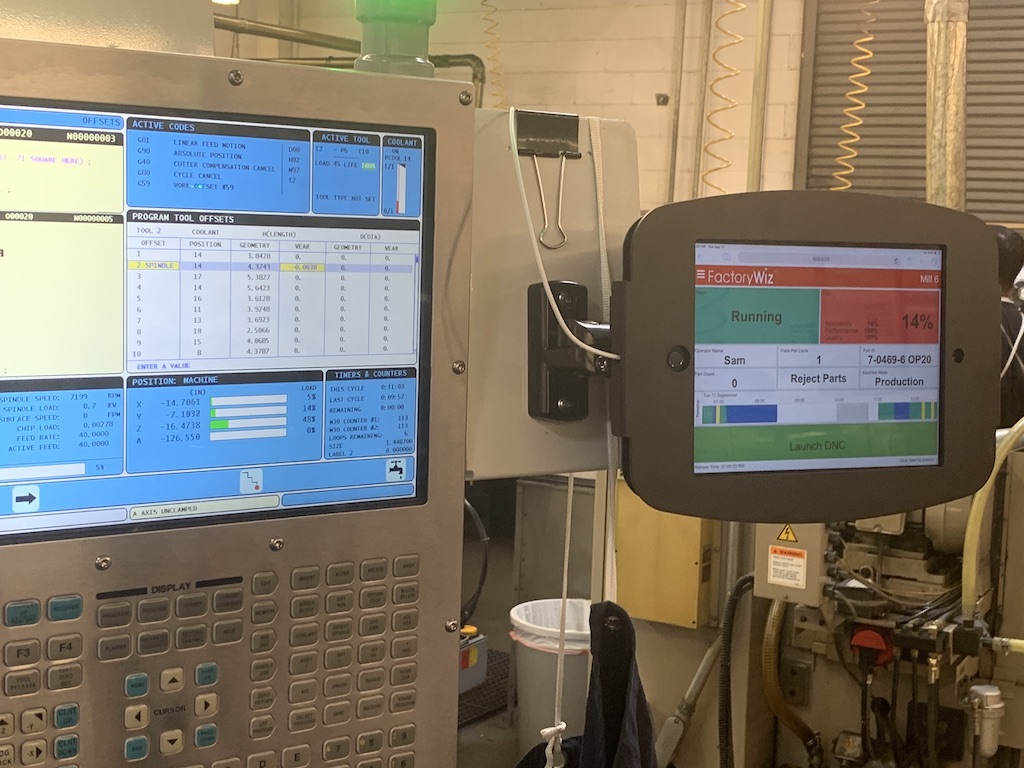

FactoryWiz can stream a whole host of data from your machines. What data, depends on the machine / control type, so check out the Machine Connections page to find out more.

Information that FactoryWiz can get automatically, with no human input:

FactoryWiz makes it easy for you to see how well your factory is performing and highlights where improvements can be made.

Configure the system to send you daily / weekly / monthly productivity reports via email. Use the productivity browser to drill down into production metrics.

Why is my machine idle?

Have the operator use their tablet attached to their machine to let you know why their machine isn't running.

From the tablet the operator can:

FactoryWiz is an open system, which means it can communicate with various other systems such as an ERP system.

Data access methods available to all customers: